However, process conditions, such as impeller operation near a liquid surface, can impose severe mechanical loads. Usually, a competent manufacturer of mixing equipment will take responsibility for the mechanical design.

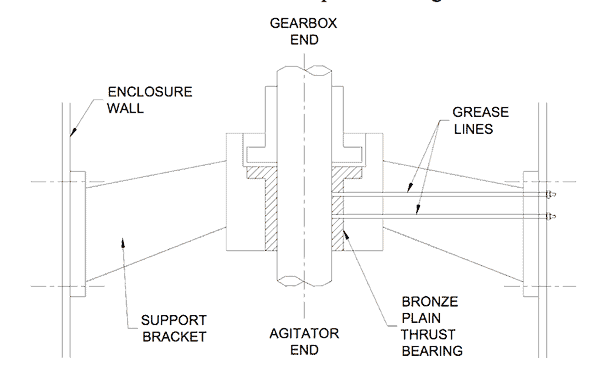

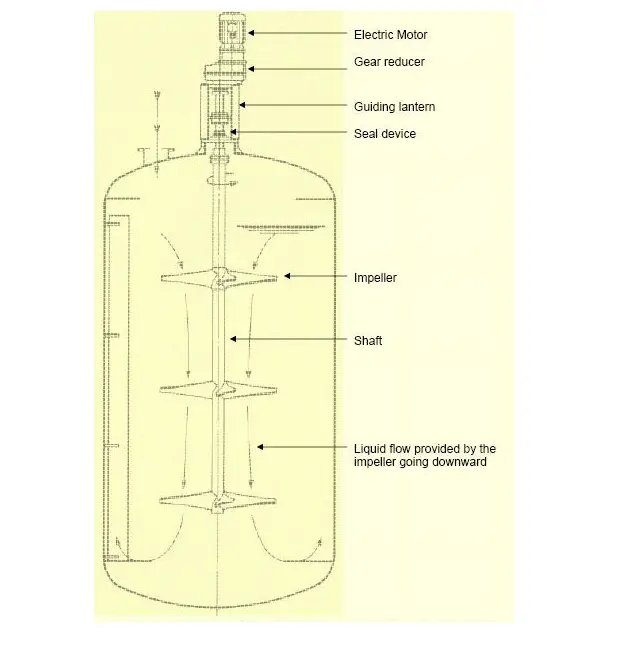

Although mixer design begins with a focus on process requirements, the mechanical design is essential for successful operation. Mixing equipment must be designed for mechanical and process operation. This review gives the complete information about agitator and parameters to be considered for design to enhance its performance. The review drives us to design an mistake prone model for agitator which will increase the mixing percentage ultimately increase the growth of industry to get right place into market with price for product. The design of agitator affects on the mixing process as proper design can increase the agitation and uniform distributions of all additives, chemicals, raw material presents in given agitator. In this paper, we have mainly focused on different parameters used for design of agitator including design of shaft, impeller blade, coupling, bearings, Hub and Keys.

Mixing of powders, pastes, paints jellies and many other products is needed to be done in many industries for many applications. All operations involving liquid phase reactions, homogenization, emulsion, dissolution, extraction, need mixing in one form or other. Mixing is very important operation in any process industry.

0 kommentar(er)

0 kommentar(er)